Choosing cooler bags may seem easy, but the wrong choices in materials, insulation, or printing can affect both function and brand image.

Custom cooler bags are fully customizable insulated bags that help keep items cold or warm while promoting your brand. They offer flexible materials, printing methods, insulation options, and accessory choices to meet different business needs, from food delivery to corporate gifts.

While many clients initially think cooler bags are simple products, we know that real customization involves much more. In the following sections, I’ll walk you through the key factors — from structure design and materials to insulation layers, printing methods, and accessories — so you can clearly understand what matters when customizing your cooler bags.

Soft cooler bags offer greater flexibility in materials and printing options. True

Soft cooler bags can be made from a variety of materials such as nonwoven fabric, cotton, Tyvek, washable kraft paper, and allow diverse printing methods for customized branding.

Soft cooler bags are only suitable for short-term use. False

With proper insulation layers like EPE foam and aluminum foil, soft cooler bags can keep items cool for several hours, even during extended outdoor activities.

Soft cooler bags, also known as soft insulated bags or thermal cooler totes, are lightweight and foldable, making them highly adaptable for a wide range of business purposes. Compared to hard coolers, soft designs offer greater flexibility in materials, shapes, and customization options.

Key Features:

Hard cooler bags, also known as hard-sided coolers or box coolers, are designed with a rigid plastic shell and high-density PU insulation. They are ideal for situations that demand long-lasting cooling and structural strength — such as outdoor camping, cold chain transport, and extended food delivery.

Key Features:

Fully Rigid Structure: Made with materials like HDPE or PP, these coolers are typically formed using injection molding or rotational molding processes. The entire body is rigid and impact-resistant, offering unmatched protection and stability.

Excellent Insulation Performance: Hard cooler bags usually contain thick polyurethane (PU) foam injected between the inner and outer walls. This structure can keep ice frozen for several days, making them perfect for camping, fishing trips, or professional cold-chain use.

Long-Term Durability: Designed to withstand heavy use, hard-sided coolers resist impact, UV rays, and rough outdoor conditions. Many models come with reinforced corners, gasket seals, and heavy-duty latches to prevent temperature loss.

Limited Branding Options: Compared to soft cooler bags, hard coolers usually offer limited space and surface compatibility for custom printing. However, some models allow for logo engraving or sticker branding, mainly for wholesale or retail channels.

Ideal Applications: Outdoor camping, fishing trips, road trips, medical cold storage, long-distance food delivery, cold chain logistics, and any setting where extended insulation is essential.

Aluminum foil is widely used as an inner lining for cooler bags. True

Aluminum foil reflects heat effectively and is commonly used as an inner insulation layer, either as smooth foil or embossed snowflake foil, providing good cooling performance.

All cooler bags use the same insulation structure inside. False

Cooler bags can have different insulation structures depending on design, including EPE foam with aluminum foil, PE foam combined with snowflake aluminum film, or PEVA/PVC linings for additional waterproof performance.

When you customize cooler bags, the outer material plays a big role. It shapes the overall appearance, reflects your brand image, and affects how durable and practical the bag will be for different uses. Here are the most common materials used for cooler bags, each offering its own unique advantages:

Nonwoven fabric is lightweight, affordable, and widely used for large promotional orders. With low minimum quantities, it’s perfect for short-term events or budget-friendly marketing projects. It’s easy to produce, supports a variety of printing options, and allows flexible design features. While it’s not as strong as woven fabrics, its cost-effectiveness makes it one of the most popular choices for corporate giveaways.

Oxford and polyester fabrics are strong, durable, and have a solid structure. They’re great for cooler bags that will be used frequently or carry heavier loads. The material holds its shape well and offers a more professional look, which is perfect for business gifts, outdoor activities, or company events. For brands that want both durability and a premium feel, Oxford is a top choice.

Cotton is a natural, eco-friendly fabric with good breathability. It helps reduce odors from repeated use and creates a soft, natural look. Brands that focus on sustainability often prefer cotton for its environmental benefits. Cotton cooler bags are popular for cultural events, non-profit organizations, and campus activities, where both practicality and brand image matter.

Laminated materials have a waterproof coating that makes them easy to clean and perfect for printing bright, eye-catching designs. Whether glossy or matte, they help brands create strong visual impact. These bags are often used for food delivery, short-distance transport, or large-scale promotions. For export orders, laminated bags made with ultrasonic sealing are thin, lightweight, and cost-effective for shipping.

Tyvek stands out with its light weight, flexibility, and unique paper-like texture. The original Tyvek material is soft and feels like fabric. After being laminated with nonwoven fabric, it becomes firmer and takes on a leather-like feel, ideal for high-end custom designs. Tyvek bags are durable, tear-resistant, water-repellent, and offer a clean surface for printing, making them popular with fashion brands, creative industries, and eco-friendly businesses.

Washable kraft paper has a natural, vintage look that feels a bit like real paper. Each bag has its own slightly different texture, giving it a handmade, unique appearance. The simple and retro style is perfect for creative brands, lifestyle products, and environmentally conscious designs. It helps brands stand out while adding a touch of quality.

If you want a more detailed comparison of cooler bag materials, check out our full guide: Top 6 Outer Materials for Custom Cooler Bags: Pros, Styles & Use Cases. It provides an in-depth look at different fabrics and their best use cases.

Heat transfer printing delivers photo-realistic prints on cooler bags. True

Heat transfer printing allows high-quality multi-color printing, including detailed designs and even realistic photos, on materials like nonwoven, cotton, oxford, and Tyvek.

UV digital printing produces better color richness than heat transfer printing. False

UV digital printing works well for logos and illustrations, but color saturation and photo realism are generally inferior to heat transfer or gravure printing.

Choosing the right printing method is key to making your custom cooler bags stand out with clear, vibrant designs and strong durability. Based on your artwork, bag materials, and order quantity, we offer several printing options:

Ideal for simple logos with solid colors or basic shapes. Produces vivid colors with sharp edges. Suitable for most materials including nonwoven, cotton, laminated, or oxford fabrics.

Best for multicolor, gradient, complex designs, or photo-style images such as real people or pets. Delivers detailed, realistic results with wide material compatibility. Applicable for nonwoven cooler bags, cotton cooler bags, oxford cooler bags, Tyvek cooler bags, polyester, and other soft insulated bags.

Mainly used for full polyester fabrics. Delivers bright, rich colors that fully penetrate the fibers, resulting in excellent color fastness and long-lasting prints. Perfect for colorful designs, cartoons, illustrations, and flat graphic styles. Less effective for photo-realistic images that require high depth or dimension.

Suitable for complex multi-color designs, including logos, icons, or illustrations. Works on many cooler bag materials with flat surfaces. Color vibrancy is generally lower than heat transfer or sublimation, and it has limited performance on highly realistic photo prints.

Primarily used for laminated materials in large-volume production. Provides precise color reproduction and smooth gradient transitions. Ideal for full-surface designs, photo-level detail, and high-end promotional cooler bags with large order quantities.

We will recommend the most suitable printing method based on your design files, bag materials, and order size. Before production, digital mockups or samples will be provided to ensure the final result meets your expectations.

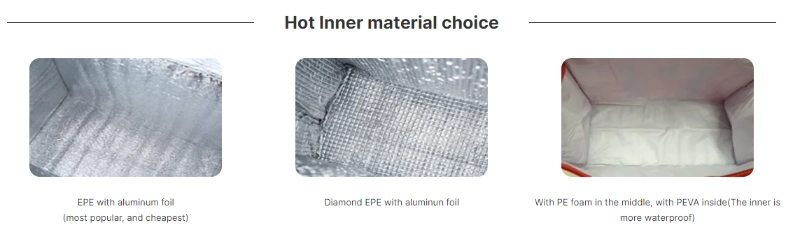

Besides the outer materials and printing methods, the internal insulation structure directly affects cooling performance, product durability, and ease of cleaning. Depending on usage needs, we offer multiple insulation structure options for custom cooler bags:

This is the most widely used standard insulation structure. EPE (Expanded Polyethylene) foam provides effective insulation and cushioning. The aluminum foil is laminated directly to the foam during production, forming a ready-to-use inner layer.

PE foam serves as an independent middle insulation layer, offering solid insulation and structural support. The exterior can be paired with different linings based on functional needs:

Offers excellent reflective insulation and easy-to-clean surfaces. Available in smooth, snowflake, or embossed finishes depending on thickness and application.

Non-toxic, eco-friendly, soft, and durable. Safe for direct food contact, widely used in insulated lunch bags, reusable food cooler bags, and daily refrigerated lunch totes.

Highly waterproof, oil-resistant, and abrasion-resistant. Often used in specialized industries or custom insulated bags requiring stronger internal protection.

We offer a variety of functional accessories that can be freely combined according to your needs:

Custom cooler bags are widely used across different industries. Depending on your business needs, cooler bags can serve various purposes while delivering strong brand visibility. Below are some common application scenarios:

| Application Area | Typical Uses | Notes |

|---|---|---|

| Outdoor & Leisure | Camping, picnics, beaches, fishing, hiking | Soft foldable cooler bags are easy to carry and store |

| Food Delivery | Meal delivery, frozen food, catering, bakery, grocery delivery | Strong insulation and easy-to-clean linings like PEVA or PVC recommended |

| Corporate Gifts & Promotions | Trade shows, employee gifts, VIP clients, anniversaries, holidays | Custom printed cooler bags offer long-term brand exposure |

| Retail & Merchandise | Eco-friendly grocery bags, branded cooler totes, seasonal gift sets | High-end materials allow premium designs for retail markets |

| Events & Festivals | Sports, concerts, school activities, team building, fundraisers | Distribute practical bags while increasing brand visibility |

| Medical & Pharmaceutical | Vaccine transport, specimen delivery, medical storage, hospital use | Require excellent insulation, waterproof lining, and sealing |

Looking for more creative ways to use insulated bags? Explore our article: 15 Smart Uses for Reusable Insulated Bags for additional practical ideas across daily life and business scenarios.

Adding PEVA or PVC lining improves waterproof performance of cooler bags. True

PEVA and PVC linings provide strong waterproof and oil-resistant properties, especially useful for food delivery bags that require frequent cleaning and moisture protection.

Sublimation printing can be applied to all cooler bag fabrics. False

Sublimation printing is limited to full polyester materials. It delivers vibrant colors but is not compatible with nonwoven, cotton, Tyvek, or laminated fabrics.

Designing custom cooler bags involves many factors. You need to consider materials, structure, insulation layers, printing methods, and how the bags will be used.

When all these elements are properly combined, you can balance cost, performance, and brand appearance effectively.

This article has provided a complete overview of the most common types, customization points, and application scenarios for custom cooler bags. It helps buyers prepare in advance for design planning and production discussions.

Yanxin Bag is a professional custom cooler bag manufacturer, specializing in producing different types of soft cooler bags, including nonwoven cooler bags, laminated cooler bags, oxford cooler bags, cotton cooler bags, Tyvek cooler bags, and washable kraft paper cooler bags.

We offer flexible customization in structure, materials, and printing. Our bags fit many business needs such as brand promotions, food delivery, corporate gifting, outdoor activities, and fresh food cold storage.

If you are looking for an experienced, flexible, and reliable custom insulated bag factory that supports both small and large orders, feel free to contact Yanxin Bag for custom solutions and sample quotes.

Looking for a meal bag that balances insulation and convenience?

This article dives into how insulated lunch bags retain temperature — covering the functions of inner and outer materials, the insulation effect of the middle layer, and the bag structures suited for hot or cold food. It also explains their usefulness in everyday life and short commutes.

Wondering whether insulated cooler bags are worth it?

This article evaluates their strengths and trade-offs — discussing compatibility between capacity and structure, ease of use, thermal performance in both directions, suitable use scenarios, material durability, maintenance simplicity, and their practicality in branding efforts.

Need to keep food warm for longer outings or deliveries?

This article outlines the key factors that affect how long insulated bags retain heat — from preheating food and internal arrangement to bag structure, insulation thickness, external temperature, duration of transport, and tips for minimizing heat loss in use.

Want your branded cooler bags to last longer?

This article provides cleaning methods tailored to different materials — including non-woven, polyester, cotton, laminated, and Tyvek bags. It explains how to preserve printed logos, maintain appearance and function, dry the bag properly, prevent mold, and prepare it for long-term storage.

Not sure if soft or hard coolers are better for your campaign?

This article compares the construction, cooling performance, look, and portability of soft versus hard cooler bags. It also analyzes which is more suitable for various uses such as outdoor trips, daily deliveries, or brand customization — helping you pick the right one for your needs.

Get a free quote and expert consultation today. Let's bring your brand vision to life.

1Discover top promotional items that can make your corporate events memorable and effective.

2Discover the importance of biodegradable materials like jute in promoting sustainability and reducing waste.

3Learn about PEVA and PVC linings to see how they contribute to waterproofing in food delivery and logistics.

Answer: Soft cooler bags are lightweight, foldable, and made from flexible materials like nonwoven fabric, cotton, Tyvek, or laminated fabrics, making them ideal for daily use, food delivery, and promotional purposes. Hard cooler bags feature rigid structures with thick foam insulation such as PE or PU foam, offering superior cooling performance for outdoor camping, long-distance transport, and cold chain logistics.

Answer: Custom cooler bags can be made from various outer materials, including nonwoven fabric, Oxford polyester, cotton, Tyvek (DuPont paper), laminated materials and washable kraft paper material etc. Each material offers different visual styles, durability, and customization options to meet specific business needs.

Answer: Popular printing methods for custom cooler bags include silkscreen printing for simple logos, heat transfer printing for multicolor and photo-realistic designs, sublimation printing for polyester fabrics with vibrant colors, UV digital printing for complex graphics, and gravure printing for high-volume laminated cooler bags requiring precise color reproduction.

Answer: Insulated cooler bags can typically keep food and beverages cold for 2 to 4 hours depending on the insulation structure, materials used, and external temperature. Adding ice packs or using thicker insulation layers like EPE foam with aluminum foil can extend the cooling duration.

Answer: Yes, custom cooler bags are widely used in food delivery services. With proper insulation materials such as PE foam, EPE foam, aluminum foil linings, and waterproof PEVA or PVC inner layers, these insulated bags maintain food temperature, prevent leakage, and ensure customer satisfaction during meal delivery, frozen food distribution, and catering.

Answer: Yes, custom cooler bags can be eco-friendly when made from materials like cotton, washable kraft paper, RPET recycled fabrics, or Tyvek. Many reusable cooler bags are designed for long-term use, reducing disposable packaging waste and supporting sustainable business practices.

Answer: The best insulation materials for reusable insulated cooler bags include EPE foam combined with aluminum foil, PE foam with snowflake aluminum layers, and multi-layer designs with PEVA or PVC linings for enhanced waterproofing. These structures provide effective temperature control for both hot and cold storage.

Answer: To clean reusable cooler bags, wipe the inner lining with a damp cloth or mild detergent. PEVA and PVC linings are easy to maintain due to their waterproof surfaces. Avoid machine washing unless specified. Proper care extends the life of custom cooler bags and maintains their insulation performance.

Answer: Custom cooler bags are often water-resistant due to inner linings like PEVA, PVC, and laminated outer layers. However, full waterproof performance depends on the seam sealing technique. Ultrasonic sealing or hot-press lamination improves waterproof capacity, especially for food delivery bags and cold chain transport cooler bags.

Order or no-order we are Always here to help you!

We will contact you within 1 working day, please pay attention to the email with the suffix “@yanxinbag.com”.

Order or no-order we are Always here to help you!

We will contact you within 1 working day, please pay attention to the email with the suffix “@yanxinbag.com”.